-

UID:317649

-

- 注册时间2020-06-19

- 最后登录2026-02-04

- 在线时间1926小时

-

-

访问TA的空间加好友用道具

|

简介:本文是以十字元件为背景光源,经过一个透镜元件成像在探测器上,并显示其热成像图。 $`%��.Y&A� �G�1�rgp>m 成像示意图 L��st���5� 首先我们建立十字元件命名为Target }R^{<�{KVJ i�^#R�iCeo 创建方法: #7�{�a~-�S N�*fN&�0�r 面1 : @�

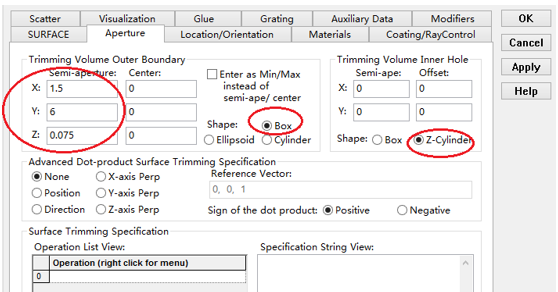

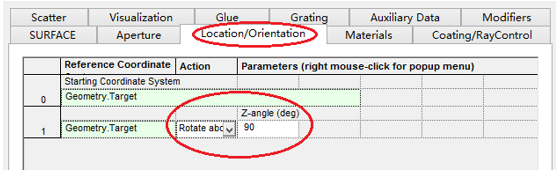

5�5�Y2 面型:plane C�$8=HM��3 材料:Air ��6�%TV� X 孔径:X=1.5, Y=6,Z=0.075,形状选择Box h(BN6ZrzKd * 7C�I q�  $3>|R�lxYA $3>|R�lxYA  ���=�$MV3] ���=�$MV3]

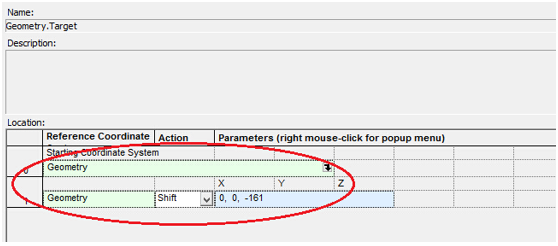

wjkN%lPfvj 首先在第一行输入temperature :300K,emissivity: 0.1; V%))%?3�x_ ct�f'/IZ5� ]BA8�[2=m� Target 元件距离坐标原点-161mm; ��

m{~�r6@ QeG�U]WU�{  �'?\Hm'�8� �'?\Hm'�8�

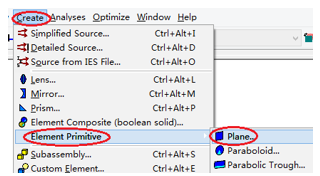

d97wiE/i<� 在菜单栏中选择Create/Element Primitive /plane il:�""x7^y 4WLB�,�<b}  +� EM� '�- +� EM� '�-

74Lq!e3hMF 光源类型选择为任意平面,光源半角设定为15度。 56�fcifXz@ gX[�6WB"�p lm$�T`�:�c 我们将光源设定在探测器位置上,具体的原理解释请见本章第二部分。 c��o�:

W!� /�gxwp:&lY 我们在位置选项又设定一行的目的是通过脚本自动控制光源在探测器平面不同划分区域内不同位置处追迹光线。 ���5'X.Z:� 8E��D6�C"6 !�aL�L|}S� 功率数值设定为:P=sin2(theta) theta为光源半角15度。我们为什么要这么设定,在第二部分会给出详细的公式推导。 1&U U�6|�X �/MA�4Er r 创建分析面: �905

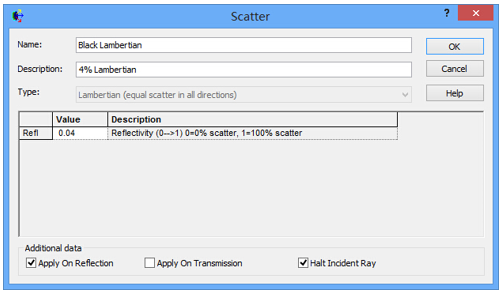

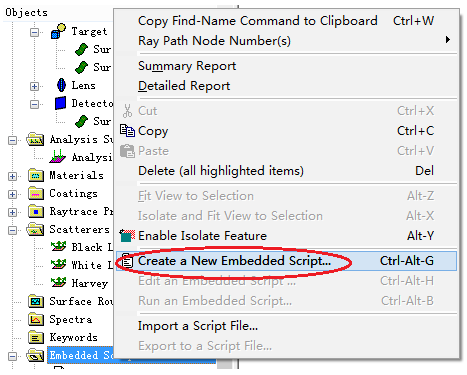

/�4z' �X"yLo8y8$ ��d�35�,[� 到这里元件参数设定完成,现在我们设定元件的光学属性,在前面我们分别对第一和第二面设定的温度和发射系数,散射属性我们设定为黑朗伯,4%的散射。并分别赋予到面一和面二。 �S^��3I"�B ^*Sb)tu\ W  }_K�7}�] 1 }_K�7}�] 1  pb�Js3uIR� pb�Js3uIR�

'raytrace j<,Ho4v}_�

DeleteRays e

*�9�c�33

CreateSource srcnode MX*T.�TG8

TraceExisting 'draw !W\Zq+^^J3

�lSW6�\j�X

'radiometry R{6�~7�<m.

For k = 0 To GetEntityCount()-1 ��7

k:w�3M

If IsSurface( k ) Then �R �k��'5L

temp = AuxDataGetData( k, "temperature" ) "�p Rr>F�a

emiss = AuxDataGetData( k, "emissivity" ) "Sx�}7?8AB

If ( temp <> 0 And emiss <> 0 ) Then �HV0!�G�-h

ProjSolidAngleByPi = GetSurfIncidentPower( k ) d;�:H#F+ (

frac = BlackBodyFractionalEnergy ( minWave, maxWave, temp ) xvpCOo�Gsz

irrad(i,j) = irrad(i,j) + frac * emiss * sigma * temp^4 * ProjSolidAngleByPi Ku��'OM6D<

End If �WF�#�3'"I

8)KA �{gN}

End If ^jph"�a� C

,q_'l?P��n

Next k ��s��*�X�E

gC�/~@Z8W]

Next j �&Y�`V�� A

nO;�*Peob�

Next i �&PE/\_xD_

EnableTextPrinting( True ) U���j/�m

f�C�M�FPhF

'write out file Ire+r�

"am

fullfilepath = CurDir() & "\" & fname �GF^)](xY+

Open fullfilepath For Output As #1 f52*s#4}�

Print #1, "GRID " & nx & " " & ny r:.ydr��@�

Print #1, "1e+308" !<EQV�q�j6

Print #1, pixelx & " " & pixely l^��~E+F~�

Print #1, -detx+pixelx/2 & " " & -dety+pixely/2 �[<0\v<{`L

3)Zd�T{�MY

maxRow = nx - 1 Tr\6�A�N?o

maxCol = ny - 1 /7`fg�0�A�

For rowNum = 0 To maxRow ' begin loop over rows (constant X) !EwL"4pPw�

row = "" G�S*Mv�{JJ

For colNum = maxCol To 0 Step -1 ' begin loop over columns (constant Y) %)t9b@�c!}

row = row & irrad(colNum,rowNum) & " " ' append column data to row string <i1�.W��!%

Next colNum ' end loop over columns dR�hsnT+KX

g� ���%ZKn

Print #1, row Ai�D�V4lHr

DQ08dP((v�

Next rowNum ' end loop over rows 3oo Tn�-`{

Close #1 a����rQ�Ei

;:`0:�Ao.

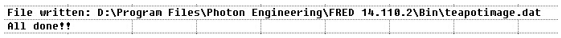

Print "File written: " & fullfilepath ���s.uw,�x

Print "All done!!" U

%,K8u|WH

End Sub f�R^aFT��

bP�+b�~�!3

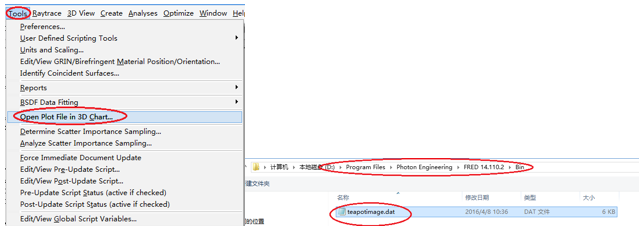

在输出报告中,我们会看到脚本对光源的孔径和功率做了修改,并最终经过31次迭代,将所有的热成像数据以dat的格式放置于: �#Rw9�I�y4

�}Gh�h%�]

�}Gh�h%�]

找到Tools工具,点击Open plot files in 3D chart并找到该文件 @lO�(�QpdG

XX9u%��BZ~ XX9u%��BZ~

打开后,选择二维平面图: [t�{ed)J

Q�>QES-�.l

|